Discover complete 2025 guide to conveyor dishwasher prices in Australia. Learn how to choose, finance, and maintain the right machine for your commercial kitchen’s volume and budget.

Key takeaways

- Price range: Expect $12,000–$35,000 for new conveyor dishwashers; flight-type models can exceed $55,000 with heat recovery.

- Types: Rack conveyors (80–180 racks/hr) for moderate volumes; flight-types (3,000–6,000 dishes/hr) for high-volume operations.

- Energy use: Rack conveyors draw about 4–10 kWh/hr; flight-types 15–30 kWh/hr—factor in your local commercial rate (~$0.30/kWh).

- Water use: Approximately 1.5–3 L per rack (150–540 L/hr at 100–180 racks/hr).

- Compliance: Must meet WaterMark AS/NZS 3500, AS/NZS 3000 wiring rules, and AS/NZS 5601 for gas units.

- Installation: Electric models $1,200–$2,500; gas/flight-type $2,000–$4,000 including backflow devices and ducting.

- Financing: Equipment loans from $10,000 to $60,000; repayments from $350–$1,000/month.

- Warranties: 12–24 months, extendable to 36 months; prioritise suppliers with national service and 5+ years parts availability.

- Throughput sizing: Align capacity to peak service—rack conveyors suit small to mid-sized venues; flight-types for large-scale catering.

- Staff training: Critical for loading, pre-rinse, and maintenance to ensure hygiene, efficiency and minimal downtime.

Introduction

If you operate a high-volume kitchen, such as in hospitality, aged care, or institutional catering, a conveyor dishwasher is often a non-negotiable piece of equipment. Unlike undercounter or pass-through models, conveyor dishwashers offer unmatched throughput, automation, and hygiene control. This guide is crafted to help Australian businesses make informed buying decisions, with detailed insights on machine types, pricing, operating costs, installation, maintenance, financing, and compliance.

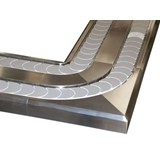

Types of conveyor dishwashers

Conveyor dishwashers are classified based on how dishes move through the system. The two primary types are:

Rack conveyor dishwashers

- Designed for dishes stacked in racks.

- Typical throughput: 100–300 racks/hour.

- Ideal for medium to large restaurants, function centres, schools, and hospitals.

Pros:

- Modular design allows for flexibility.

- More energy- and water-efficient for moderate volumes.

Cons:

- Manual loading/unloading of racks required.

Flight-type conveyor dishwashers

- Dishes are placed directly onto a moving belt.

- Typical throughput: 5,000–8,000+ dishes/hour.

- Suitable for very high-volume environments like large hotels, hospitals, or airports.

Pros:

- Maximum automation.

- Higher efficiency at scale.

Cons:

- Higher upfront and installation costs.

- More space required.

Conveyor dishwasher prices in Australia

The price of a conveyor dishwasher in Australia can vary significantly depending on the machine type (rack vs. flight), size, energy efficiency, brand, and whether it includes premium features such as heat recovery systems or automatic rinse functions. Here's what you can expect:

Rack conveyor dishwashers:

- Entry-level models start from around $12,000 and are ideal for smaller hospitality venues or aged care facilities.

- Mid-range units typically range between $17,000 and $22,000, offering better throughput and improved energy efficiency.

- High-end machines with advanced automation and lower water usage can exceed $28,000.

Flight-type conveyor dishwashers:

- Base models begin at approximately $25,000.

- Mid-tier options fall within the $35,000 to $45,000 range.

- Top-of-the-line units with large-scale throughput and energy recovery systems often cost $55,000+.

Additional costs buyers should budget for:

- Installation costs: Expect to pay $1,500 to $3,500, depending on existing site infrastructure and access.

- Water filtration systems: These help extend the life of your machine and reduce spotting, typically priced at $500 to $2,000.

- Chemical dispensers: Essential for accurate dosing of detergents and rinse aid, usually costing between $300 and $800.

Operation and throughput

Conveyor dishwashers are designed for continuous operation during peak service periods. Key performance indicators include:

- Racks per hour: Affects how many staff and shifts are required.

- Cycle duration: Average cycle time is 90–120 seconds per rack.

- Noise levels: Modern machines range from 65–75 dBA, suitable for commercial kitchen environments.

Utility consumption (approximate averages):

- Electricity: 10–25kWh/hour

- Water: 160–250 litres/hour

- Detergent and rinse aid: ~$0.10–$0.20 per cycle

Maintenance and parts

Routine maintenance is critical for efficiency and lifespan.

Daily tasks:

- Clean filters and spray arms

- Check detergent levels

- Inspect for debris in conveyor belts

Weekly tasks:

- Descale heating elements

- Check gaskets and seals

- Clean water tanks

Parts that may require periodic replacement:

- Conveyor drive chains and motors

- Wash/rinse pumps ($500–$2,000)

- Thermostats and control boards ($300–$800)

Most suppliers offer preventive maintenance contracts, ranging from $800 to $2,000/year.

Financing options in Australia

Purchasing a conveyor dishwasher can be capital-intensive. Equipment finance options offer flexibility:

Options include:

- Chattel mortgage (ownership with depreciation benefits)

- Lease agreements (operating lease with upgrade flexibility)

- Hire purchase (fixed term with balloon payment)

Typical terms:

- Loan amounts: $10,000 to $60,000

- Terms: 12–60 months

- Monthly repayments: Starting from ~$350/month depending on credit profile and term

Many lenders offer pre-approval within 24–48 hours with minimal documentation for commercial kitchens.

Warranties and support

Conveyor dishwashers are long-term investments and should be backed by strong support.

Typical warranty terms:

- Standard: 12 months parts and labour

- Extended warranties: Up to 3 years available at extra cost

Look for:

- National servicing network

- Spare parts availability (at least 5–10 years post-manufacture)

- Inclusions like emergency support or loan equipment

Compliance and certification in Australia

Commercial dishwashers must meet safety and plumbing regulations. Key compliance points include:

- WaterMark Certification (AS/NZS 4020): Ensures water safety.

- Backflow prevention: Required by local councils.

- Electrical compliance: Must be installed by a licensed electrician, especially for 3-phase models.

- Gas connection (if applicable): Compliance with AS/NZS 5601.

It’s important to consult your local council or water authority, as compliance requirements may vary between NSW, VIC, QLD and other jurisdictions.

Space and installation planning

Typical machine dimensions:

- 1-tank rack conveyor: ~1300mm (L) x 750mm (W) x 1500mm (H)

- Multi-tank or flight-type: Up to 3500mm long or more

Other planning considerations:

- Floor drainage under the machine

- Adequate ventilation, especially if no heat recovery unit is installed

- Noise isolation where kitchen layout is open-plan

- Installation costs: $1,500 to $3,500 depending on complexity

Operational throughput and sizing guidance

Choosing the right conveyor dishwasher starts with understanding your kitchen’s throughput needs. Oversizing wastes space and energy; undersizing creates bottlenecks that impact service quality.

Here’s how to align dishwasher capacity with your venue’s volume:

- Estimate racks per hour required

- A general rule is 1 rack per 20–25 meals. For example, a venue serving 500 meals per day during peak hours may require a machine capable of handling 25–30 racks per hour, especially if crockery and cookware are processed simultaneously.

- Consider peak vs off-peak demands

- Conveyor dishwashers are most efficient during sustained high-volume operation. If your service has sharp peaks (e.g. schools, hospitals, functions), choose a model with rapid recovery and auto-loading to maintain pace.

- Understand machine output benchmarks

- Rack conveyor dishwashers typically process 100 to 280 racks per hour, depending on model and settings.

- Flight-type conveyors suit very high-volume sites, with output ranging from 3,000 to 8,000 dishes per hour.

- Account for kitchen footprint

- Conveyor models can span 2 to 5+ metres in length, including infeed and outfeed tables. Ensure your kitchen layout allows for:

- Ergonomic loading/unloading

- Adequate clearance for maintenance

- Access to drainage, power, water and chemical lines

- Budget for modular expansion

- Many commercial conveyor units are modular and can be extended with additional drying zones, pre-rinse arms, or stacking conveyors to meet growing demand. Ask the supplier about expansion compatibility before purchase.

Staff training and workflow design

Proper integration of a conveyor dishwasher can significantly improve staff efficiency, hygiene compliance, and workplace safety. However, effective use requires structured staff training and smart kitchen layout planning.

Here’s how to optimise performance through workflow design:

- Train for multi-zone operation

- Conveyor dishwashers require coordination across multiple zones: pre-rinse, loading, unloading, and drying. Staff should be trained to:

- Scrape and stack dishes uniformly to avoid jams

- Load racks consistently to maximise pass-through efficiency

- Recognise error signals (e.g. temperature faults or detergent alerts)

- Implement pre-rinse protocols

- Manual or automated pre-rinse stations save water and reduce residue build-up in the machine. Ensure team members understand:

- What needs to be rinsed manually (e.g. pots, burnt pans)

- The importance of maintaining filters and spray arms

- Set up a U-shaped or linear workflow

- Design your kitchen so dishes move logically from dirty to clean without backtracking. Typical conveyor setups benefit from:

- Dirty dish drop-off zone → pre-rinse → dishwasher inlet

- Outlet area with drying racks → clean dish storage

- Standardise rack types and use

- Using consistent rack types (e.g. for glasses, plates, cutlery) speeds up loading and reduces cycle times. Clearly label and train staff on proper use.

- Schedule refresher training

- Staff turnover is common in hospitality. Arrange refresher training every 6–12 months, particularly if you upgrade detergents, introduce digital features, or change your workflow.

- Promote accountability

- Assign responsibility for machine hygiene (filters, waste traps, inspection hatches) to designated staff to ensure daily maintenance is performed and logged.

By embedding training into onboarding and laying out your kitchen to match dishwasher flow, you'll get the most out of your investment — reducing cycle time, errors, and detergent waste while boosting food safety compliance.

Common questions buyers ask

1. How do I size a conveyor dishwasher for my kitchen?

- Estimate racks/hour required during peak service. Most medium kitchens do 100–150 racks/hour.

- Consider future growth to avoid under-sizing.

2. Should I choose electric or gas-powered?

- Electric is more common and easier to install.

- Gas may have lower long-term energy costs but requires more complex setup.

3. Can I claim depreciation or tax deductions?

- Yes, under ATO asset depreciation rules, especially if financed via chattel mortgage.

4. What’s the lead time for delivery and installation?

- For stocked models: 3–10 business days.

- For imported/custom setups: 4–8 weeks.

5. What support is available post-purchase?

- Most suppliers offer service plans, emergency repair, and access to authorised technicians.

Final thoughts

A conveyor dishwasher is more than a machine, it’s the backbone of your kitchen’s hygiene and turnaround capacity. Choosing the right model involves balancing throughput, running costs, space, and compliance. With price points starting from around $12,000 and scaling with your needs, investing in a conveyor dishwasher can drive serious efficiencies for medium and large-scale commercial kitchens in Australia.

Carefully consider your operation’s peak demands, available space, and utility infrastructure before buying. Ensure your supplier provides adequate post-sales support, warranty, and compliance guidance. For those needing flexibility, explore commercial finance solutions that align with your budget.

When chosen and implemented wisely, a quality conveyor dishwasher will save you time, labour, water, and electricity, helping your operation stay sharp, compliant, and cost-efficient in 2025 and beyond.

-160x160-state_article-rel-cat.png)