Discover how Australian businesses can streamline stocktaking without interrupting daily operations. Learn time-saving strategies and tools that keep service running smoothly.

Key takeaways

- Stocktaking efficiency is crucial to maintain uninterrupted service and customer satisfaction in Australian businesses.

- Advanced inventory technology like RFID and cloud-based systems reduce manual errors and speed up processes.

- Strategic scheduling and phased stocktaking minimise disruption during peak trading hours.

- Staff training and clear communication are essential to ensure smooth stocktaking without impacting frontline operations.

- Compliance with Australian accounting and taxation laws ensures accurate reporting and audit readiness.

- Industry-specific stocktaking requires tailored strategies to minimise disruption, ensure compliance, and maintain operational continuity, whether in retail, hospitality, healthcare, or manufacturing.

- Case studies from retail and hospitality sectors demonstrate practical approaches to effective, low-impact stocktaking.

Introduction: Why seamless stocktaking matters in Australia’s competitive market

In Australia’s fast-paced retail and hospitality industries, stocktaking remains a critical yet often disruptive task. It ensures accurate inventory records, prevents losses, and supports financial reporting, but traditional stocktakes can halt service, frustrate staff, and alienate customers.

With consumer expectations rising and competition intensifying, your ability to carry out stocktakes without interrupting daily operations is a competitive advantage. This article explores how Australian businesses can modernise stocktaking with practical strategies, emerging technologies, and compliance best practices that keep service smooth and operations transparent.

Understanding the challenges of stocktaking without disruption

Stocktaking traditionally involves closing stores or service areas to count inventory accurately. This causes:

- Lost sales and customer dissatisfaction during downtime

- Pressure on staff to work overtime or off hours, leading to fatigue and errors

- Risk of inaccurate counts if rushed or poorly planned

- Compliance risks if stock levels are misstated during audits or tax reporting

Australian businesses face additional complexity from supply chain disruptions and seasonal demand fluctuations, making timely stocktaking more critical yet challenging.

Leveraging technology to streamline stocktaking

Investing in technology is key to reducing disruption while improving accuracy. Leading Australian businesses are adopting:

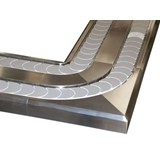

- RFID tagging and scanners: Enables rapid, real-time counting without unpacking shelves, speeding up stocktakes dramatically.

- Cloud-based inventory management systems: Provide up-to-date stock data accessible by multiple locations and mobile devices.

- Mobile scanning apps: Allow staff to conduct counts on the floor during live service hours, minimising need for closures.

- Automated reconciliation tools: Help quickly identify discrepancies and streamline adjustments.

Example: Woolworths has invested heavily in RFID and integrated stock management, reducing manual stocktake times by 40%, resulting in fewer disruptions to store operations.

Scheduling stocktakes to minimise impact

Timing and planning are crucial. To reduce service interruption:

- Conduct phased or cycle counts: Instead of full stocktakes, count inventory in sections over time during quieter periods.

- Schedule during off-peak hours or slow seasons: Utilise early mornings, late nights, or low-demand days for stocktaking activities.

- Use predictive analytics: Forecast busy periods to avoid clashes and optimise timing.

Case study: A Melbourne-based café chain implemented overnight stocktakes combined with cycle counting, allowing stores to remain open during trading hours without sacrificing inventory accuracy.

Empowering your team with training and communication

Your staff play a vital role in smooth stocktaking:

- Train staff on efficient counting techniques and technology use.

- Communicate clearly about stocktaking schedules and roles to manage expectations and reduce errors.

- Foster a culture of accuracy and accountability to encourage diligent stock recording.

Australian workplace standards also require consideration of overtime, breaks, and fair rostering during stocktaking periods.

Compliance and audit considerations for Australian businesses

Stocktaking impacts financial reporting and taxation. Ensure compliance by:

- Adhering to Australian Accounting Standards (AASB 102) on inventory measurement and disclosure.

- Maintaining accurate, auditable records to support GST reporting and potential audits by the Australian Taxation Office (ATO).

- Implementing internal controls and segregation of duties to prevent fraud and errors.

Regular stocktakes also assist in compliance with workplace health and safety regulations, reducing risks from overcrowded stockrooms or manual handling incidents.

Industry-specific considerations for stocktaking without disruption

Retail stocktaking: Balancing inventory accuracy with customer flow

- Key challenges: High foot traffic, multiple product categories, seasonal stock fluctuations.

- Equipment: Handheld barcode and RFID scanners, mobile POS integration, real-time inventory management systems.

- Best practices: Cycle counting during off-peak hours, using stock robots or automated shelf scanners (emerging tech in larger stores), and implementing dedicated stocktake teams to minimise impact on sales floors.

- Example: An Australian fashion retailer uses overnight stocktakes combined with mobile scanning to maintain seamless shopping experiences.

Hospitality stocktaking: Managing perishables and service continuity

- Key challenges: Tracking perishable goods, rapid stock turnover, synchronising kitchen and bar inventories.

- Equipment: Inventory management software integrated with POS systems, digital scales, mobile counting devices.

- Best practices: Regular mini-counts during shift changes, utilising cloud-based systems for real-time updates, and scheduling full stocktakes during closed hours or slow weekdays.

- Example: A Sydney café chain conducts daily mini stocktakes during afternoon lulls to keep kitchens stocked without affecting service.

Healthcare and aged care stocktaking: Compliance and safety focus

- Key challenges: Strict regulatory requirements, expiry date tracking, controlled substances management.

- Equipment: Barcode scanners with expiry date capture, specialised inventory software with audit trails, secure storage systems.

- Best practices: Scheduled audits aligned with regulatory reporting, staff training on compliance and safety protocols, and phased counting to avoid service interruptions.

- Example: An aged care facility in Victoria uses RFID tagging for medical supplies, enabling faster and more accurate stocktakes without disrupting resident care.

Manufacturing and warehousing: Large-scale inventory and accuracy demands

- Key challenges: Bulk stock, multiple SKUs, integration with supply chain systems.

- Equipment: Industrial RFID readers, warehouse management systems (WMS), handheld mobile computers with scanning capabilities.

- Best practices: Using cycle counting programs aligned with production schedules, real-time data syncing, and utilising automated inventory drones or robots where feasible.

- Example: An Australian food manufacturer employs overnight cycle counts with integrated WMS to keep production running smoothly during the day.

Practical tips and tools for seamless stocktaking

- Use barcode or RFID scanners integrated with your inventory system.

- Automate data capture to reduce manual entry errors.

- Break stocktakes into manageable shifts or sections.

- Involve cross-functional teams for accurate and efficient counts.

- Use real-time reporting dashboards for instant insights and quicker decision-making.

- Consider outsourcing stocktaking to specialised providers for large or complex operations.

Conclusion: Turning stocktaking into a service advantage

In Australia’s competitive retail and hospitality markets, stocktaking doesn’t have to be disruptive. By embracing technology, planning strategically, and investing in your people, you can maintain service continuity while ensuring inventory accuracy and compliance.

Ultimately, seamless stocktaking improves customer experience, supports better business decisions, and safeguards your bottom line, giving you an edge in a demanding market.

-160x160-state_article-rel-cat.png)